|

gtanno189899-97

Location:

T171 .G42 G49x 1888-1899

Title: Date:

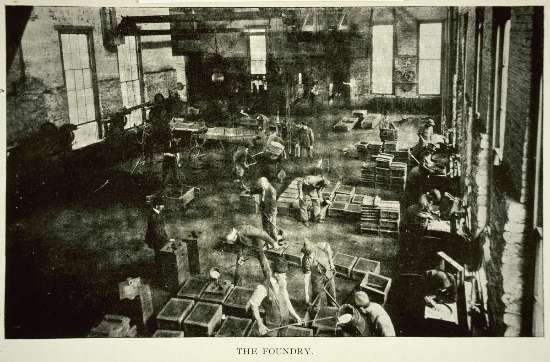

The foundry

1899?

Content:

Image of student workers working in the Foundry pouring moulds.

History:

The Shop Building contained a foundry, forge, boiler room and engine room to support the learning of wood

work and metal work, with a view to designing and building working engines. The Shop Building also served

as the school's physical plant. In the early hours of April 21, 1892, the Shop Building was destroyed by

fire. In the interests of economy, it was decided that the new Shop Building would be built according to

the original design. The Announcement of the time notes: "The workshop is also of brick, two hundred and

fifty feet long by eighty wide and two stories high. It is beautifully designed with reference to its use,

and affords ample space for the various departments of instruction pursued in it. It contains boiler and

engine rooms, wood shop, machine shop, forge room, and foundry. It has been equipped with a full

assortment of tools, both hand and machine, by the best manufacturers. The shops are organized and managed

as a manufacturing establishment, and the facilities are necessarily such as will give the best possible

results. The shops are organized and managed as a manufacturing establishment, taking contracts for a great

variety of work, both in wood and iron, and from this variety of work, always in process of construction,

such parts are given the student to make as will afford him the best instruction at that particular stage

of his course." The Georgia School of Technology Announcement of 1898-99 notes: "The foundry, which is

unlike most foundries in being a bright, cheerful place, is throroughly equipped, having besides a main

moulding-room with a floor area of 40x90 feet, a core-room, two ovens for baking cores, a Collieau cupola

in a fireproof annex having iron charging-floor and iron roof, a separate building in which are placed the

rumblers and the pickling vats, and another building for the brass foundry. So far as we are aware, we

have the only equipment south of Cincinnati prepared to make bronze vault-doors (upon which we received a

gold medal at the Cotton States and International Exposition). We take great pride in our foundry-work,

and it is justly famed for being of the highest class. Foundry-work in this section of the country has

been of an exceedingly low grade, and we feel that the work we are doing in this field alone justifies the

annual expenses of the shops. In the foundry, the student is given careful and efficient instruction in

green and dry-sand moulding, core-making, mixtures of iron, brass-founding, and the mixtures of the various

useful bronzes, aluminum-casting, and the aluminum bronzes. There is also a separate cupola for the

reduction of "burnt-out" pure copper electric wire to pure pig lake copper."