|

gtanno189899-69

Location:

T171 .G42 G49x 1888-1899

Title: Date:

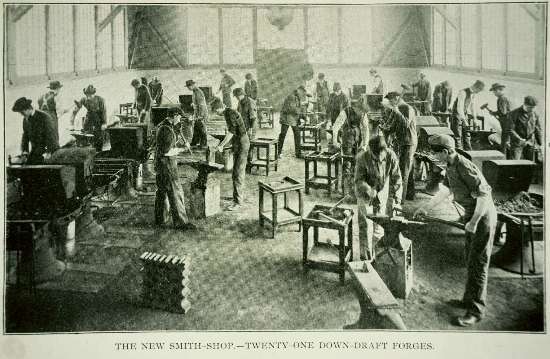

The new smith shop - twenty-one down-draft forges

1899?

Content:

Image of students working in the Smith Shop. Alternate title reads: Twenty-one down-draft forges.

History:

From the 1898-1899 Announcement: "The distinctive feature of this school is the meachanical workshops. It

is safe to say that in no other school in our country is so much emphasis placed on the importance of the

practical skill and experience to be gained in machine-shop work of the very highest class.. The first or

Apprentice year is devoted entirely to wood-work.. Throughout the remaining three years, each student

devotes one day each week to work in the shops..The work in the second, third and fourth years (Junior,

Middle and Senior) is divided between the four departments of the shop, viz. Pattern-making, foundry,

smith-shop and machine-shop.. Durng the present year, the smith-shop has been enlarged and rebuilt entire.

It is 37x70 feet with all four sides solid glass. It is equipped with twenty-one forges, with Peter

Wright's best forged anvils, and blast pipes and smoke ducts under ground. Smoke is carried away by a

powerful exhaust fan, on the down-draft system, leaving the overhead space entirely free for admission of

light. In one end are the foreman's office and a room fitted up with benches and vises for bench-work in

forging. The smoke-exhaust fan is located overhead in the foundry (in another building) and the system

works admirably. A more efficient and cheerful blacksmith shop it would be difficult to imagine. All the

shops are lighted with electricity, both arc and incandescent. In the smith-shop, the student is first

given to purely manual-training tasks in iron-forging, which are continued only so far as will enable him

to acquire sufficient skill to forge some useful article. After that his work is confined to such articles

as possess intrinsic value. We received a silver medal at the Cotton States and International Exposition

on our display of small tools made in the smithery, such as hammers, masons' and moulders' trowels and

tools, turning chisels and gouges, cold-chisels, swages, spawls, etc. The student also acquires skill in

forging and dressing lathe and planer tools; welding, tempering and annealing steel; the blazing and

soldering of various metals, case hardening, bluing, etc. It is to be distinctly understood that the

student does not simply observe these operations as they are performed by a skilled artisan, but is

required to acquire the handicraft himself, under expert instruction."